Description

We are excited to announce our 164×20 rifle drilled drop-in connecting rods for VR6 engines designed to work with stock or aftermarket pistons. Our connecting rods have been engineered for larger turbo and boost applications while maintaining reliability.

Rifle Drilled

All CTS connecting rods are rifle drilled as standard. Factory rod bearings are not drilled but can be used. Drilled bearings are no longer available from the manufacturer.

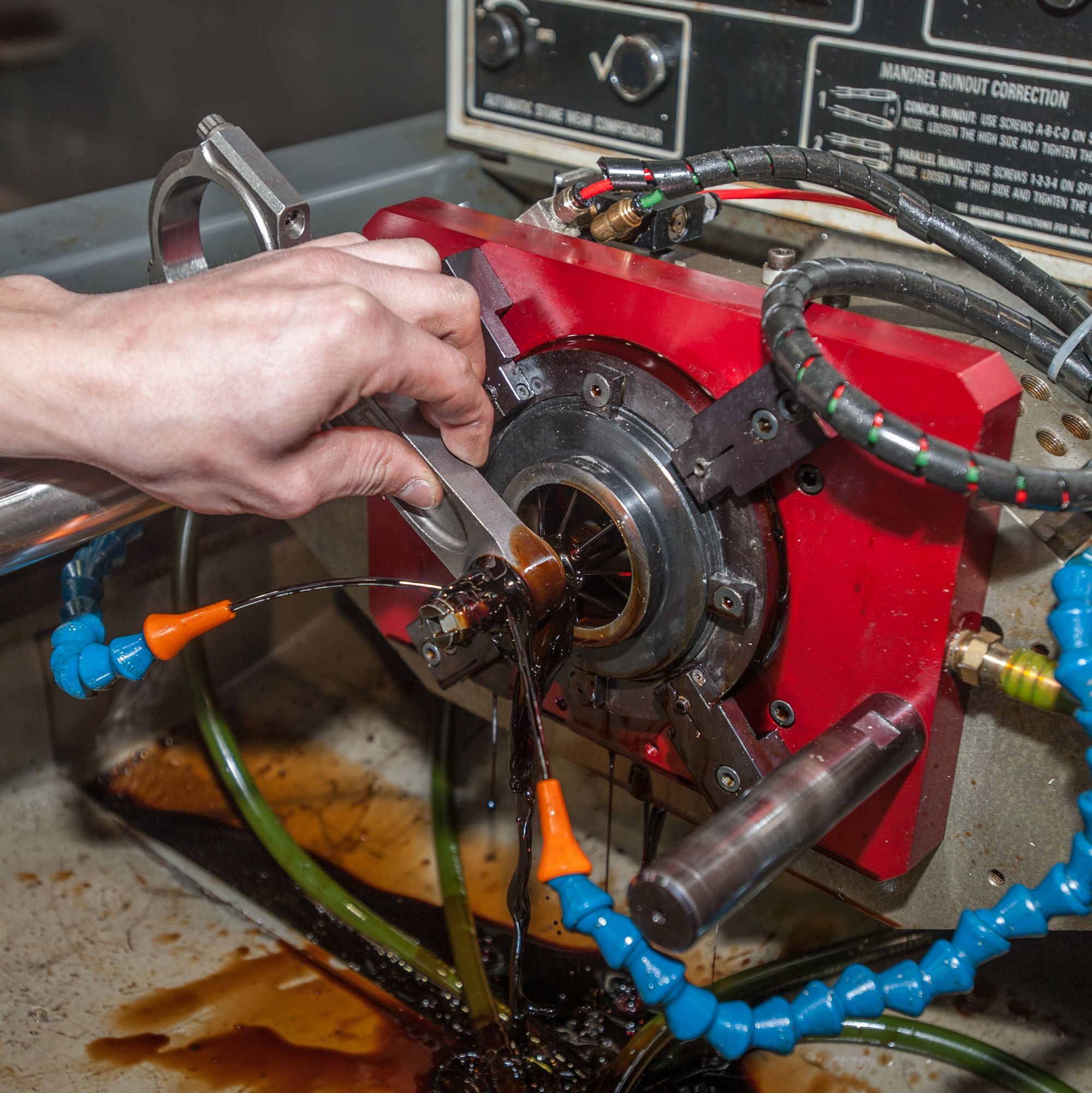

Honing

All big and small end bores are honed in house on precision equipment to exacting tolerances.

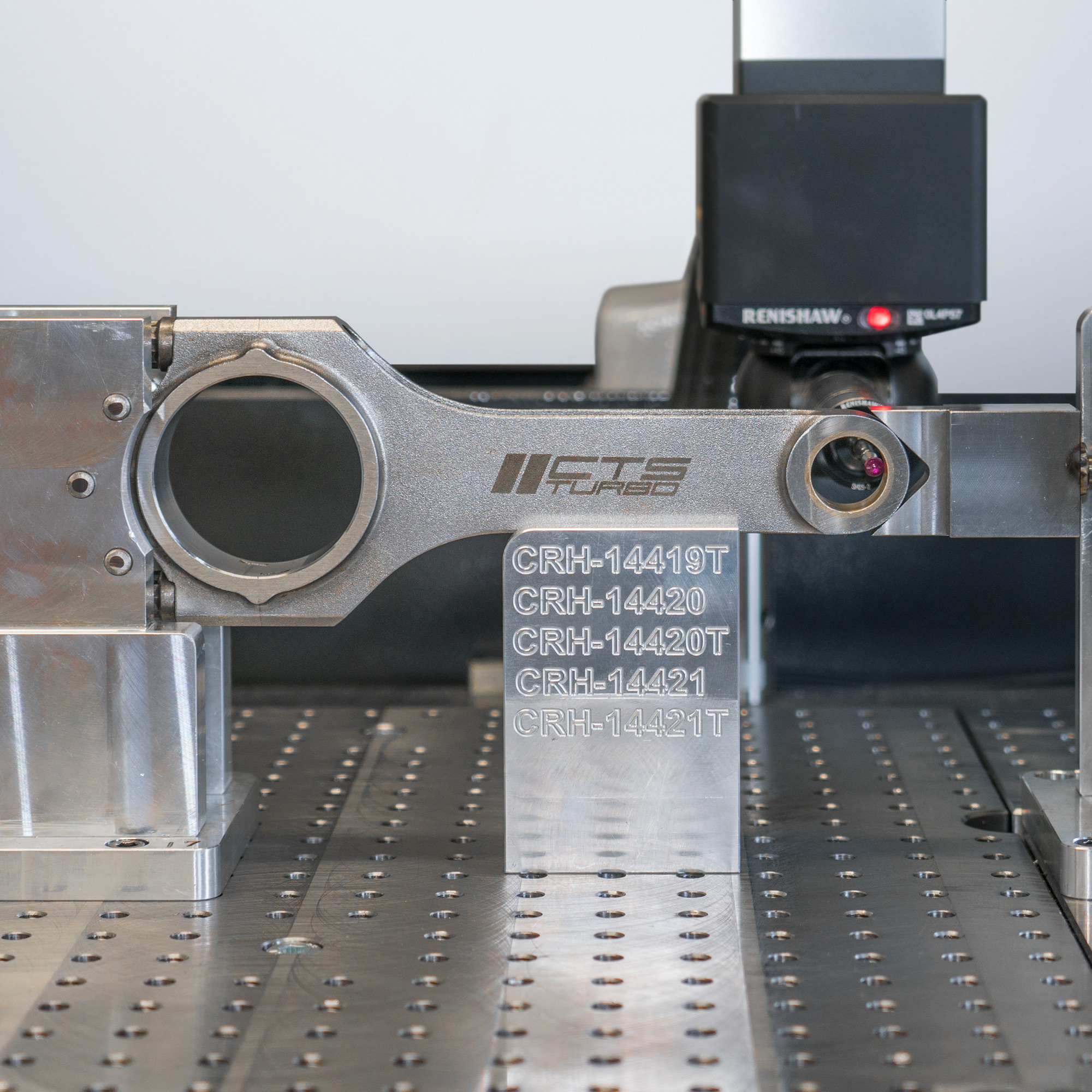

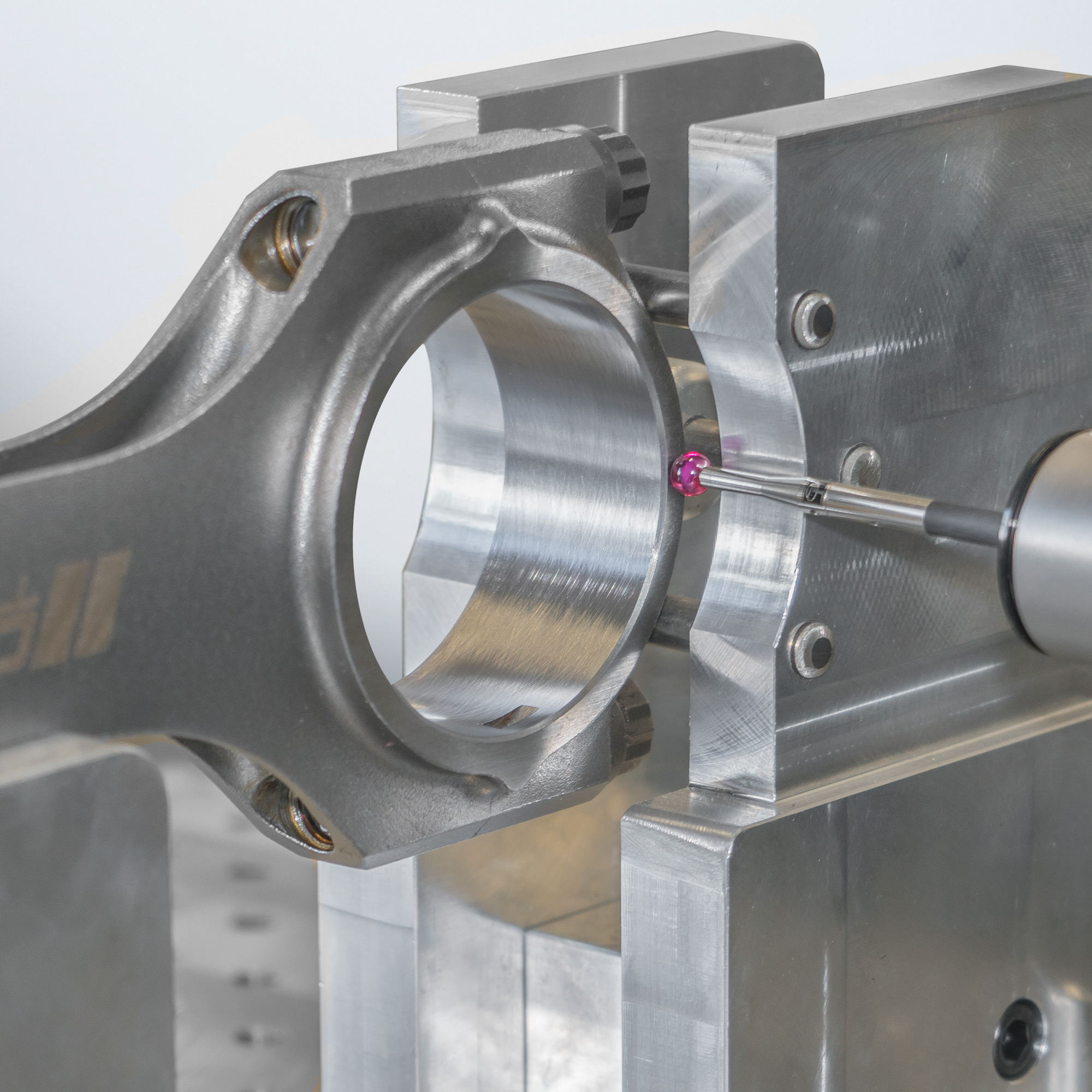

Quality Control

All connecting rods are put through a stringent quality control process including measuring all critical dimensions on our state of the art CMM (coordinate measuring machine). All connecting rods are matched in weights +/- 1 gram.

ARP Bolts

All CTS Turbo connecting rods come standard with genuine ARP 2000 rod bolts.

Product Specifications

- Center to Center: 164mm

- Wrist Pin Diameter: 20mm

- Big End Journal Width: 19.9mm

- Wrist Pin Style: Non-tapered

- Big End Journal Diameter: 50.60mm

- Rod Bolt Dimensions: 5/16″

Fitment

- 12V VR6 2.8L

- 24V VR6 2.8L

- 24V VR6 3.2L

Additional information

| Weight | 14 lbs |

|---|---|

| Dimensions | 12 × 8 × 6 in |